Managing Lots and Traceability¶

The double-entry management in OpenERP enables you to run very advanced traceability. All operations are formalized in terms of stock moves, so it is very easy to search for the cause of any gaps in stock moves.

Note

Upstream Traceability

It runs from the raw materials received from the supplier and follows the chain to the finished products delivered to customers. (Note that the name is confusing - this would often be considered a downstream direction. Think of it as Where Used.)

Note

Downstream Traceability

It follows the product in the other direction, from customer to the different suppliers of raw material. (Note that the name is confusing - this would often be considered an upstream direction. Think of it as Where Supplied.)

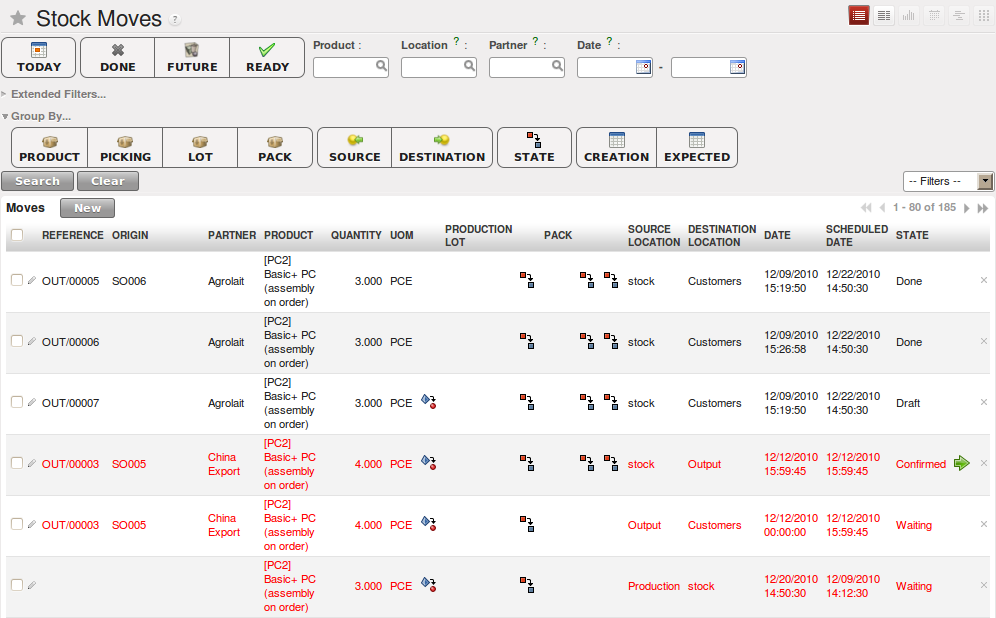

Stock Moves¶

Use the menu Warehouse ‣ Traceability ‣ Stock Moves to track past stock transactions for a product or a given location. All the operations are available. You can filter on the various fields to retrieve the operations about an order, or a production activity, or a source location, or any given destination.

Each stock move is in a given state. The various states are:

- Draft : the move so far has no effect in the system. The transaction has not yet been confirmed,

- Not available: the move will be done, so it will be counted in the calculations of virtual stock. But you do not know whether it will be done without problem because the products have not been reserved for the move,

- Available : the move will be done and the necessary raw materials have been reserved for the transaction,

- Done : the stock move (picking) has been done, and entered into the calculations of real stock,

- Waiting : in the case of transactions From Order, this state shows that the stock move is blocked waiting for the end of another move,

- Cancelled : the stock move was not carried out, so it is not taken into account in either real stock or virtual stock.

Delivery orders, goods receipts and internal picking lists are just documents that group a set of stock moves. You can also consult the history of these documents using the menu Warehouse ‣ Traceability ‣ Packs.

Lots¶

OpenERP can also manage product lots. Two lot types are defined:

- Production lots (batch numbers) are represented by a unique product or an assembly of identical products leaving the same production area. They are usually identified by bar codes stuck on the products. The batch can be marked with a supplier number or your own company numbers.

- Tracking numbers are logistical lots to identify the container for a set of products. This corresponds, for example, to the pallet numbers on which several different products are stocked.

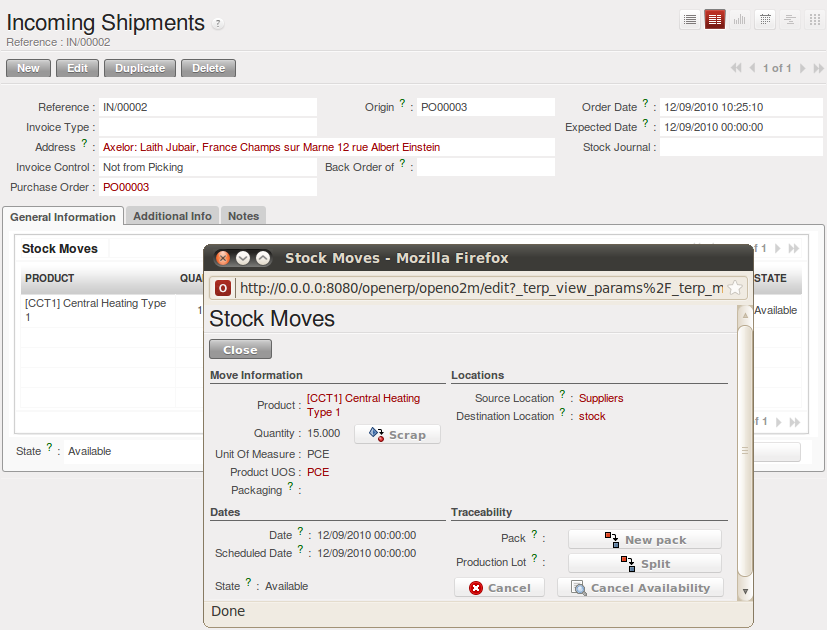

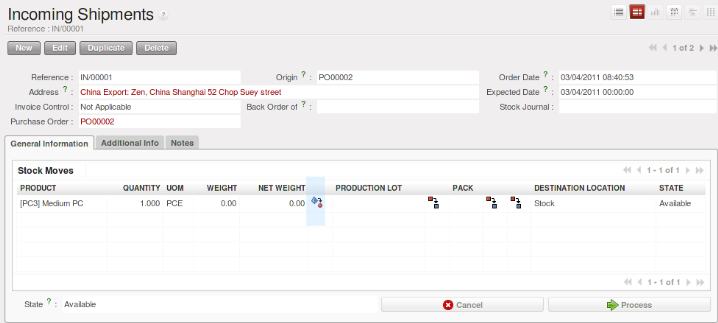

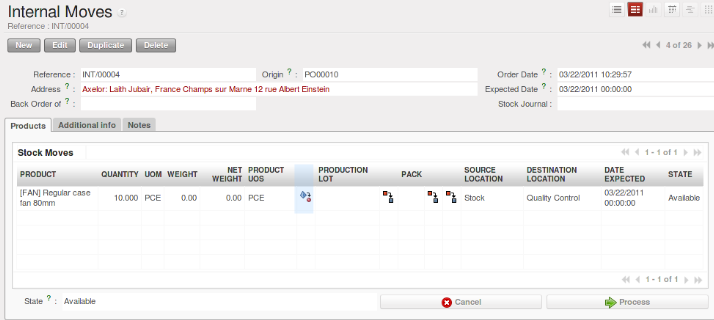

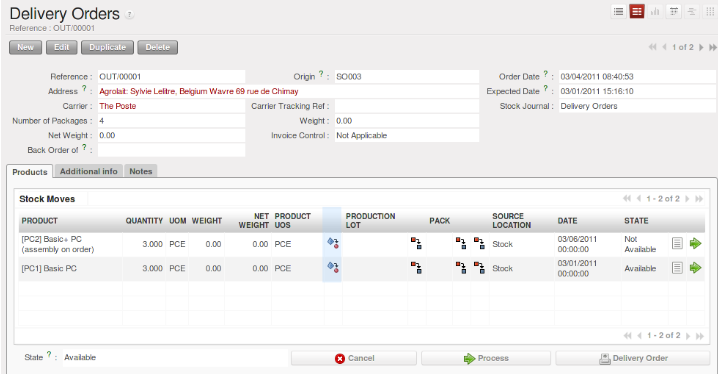

These lots can be encoded onto all stock moves and, specifically, on incoming shipments lines, internal moves and outgoing deliveries.

To enter the lot number in an operation, you can use an existing lot number or create a new pack. A production lot (batch number) is used for a single product. A tracking number can be used several times for different products, so you can mix different products on a pallet or in a box.

Note

Simplified View

In the Simplified view, the tracking numbers cannot be seen: the field is hidden. To get to Extended view mode, assign the group Useability / Extended View to the current user, or change the User Preferences.

You can also specify on the product form the operations in which a lot number is required. You can then compel the user to set a lot number for manufacturing operations, goods receipt, or customer packing.

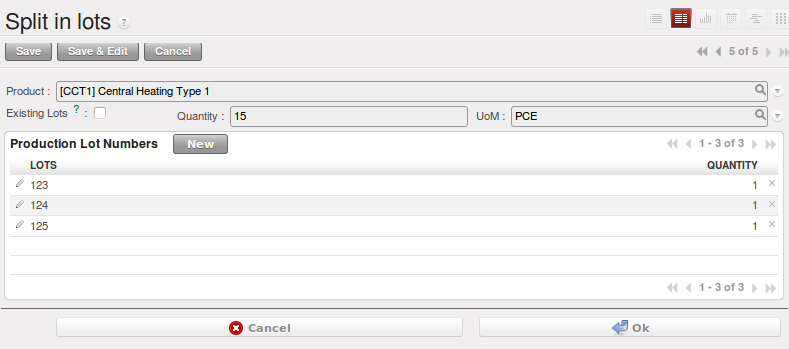

You do not have to encode the lot numbers one by one to assign a unique lot number to a set of several items. You only need to take a stock move for several products line and click the button Split in Production Lots. You can then give a lot number prefix (if you want) and OpenERP will complete the prefix in the wizard with a continuing sequence number. This sequence number might correspond to a set of pre-printed barcodes that you stick on each product.

Traceability¶

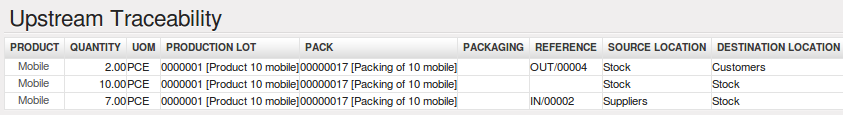

If you key in the lot numbers for stock moves as described above, you can investigate the traceability of any given lot number. Go to the menu Warehouse ‣ Traceability ‣ Production Lots or Warehouse ‣ Traceability ‣ Packs.

Tip

Product Shortcuts

From the product form, the toolbar to the right offers useful information:

- Minimum Stock Rules,

- Stock by Location,

- Product Sales,

- Bills of Material.

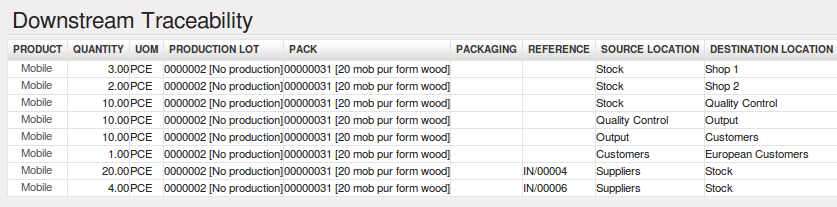

Search for a particular lot using the filters for the lot number, the date or the product. Once you can see the form about this lot, several actions can be performed:

- Upstream Traceability: from supplier through to customers,

- Downstream Traceability: from customer back to suppliers,

- Stock in all the physical and virtual locations.

Finally, on a lot, you can enter data on all the operations that have been done for the product. That keeps a useful history of the pre-sales operations.

Scrapping Products¶

In OpenERP, there are many ways to handle scrap products.

Warehouse ‣ Product Moves ‣ Receive Products

Warehouse ‣ Product Moves ‣ Deliver Products

Warehouse ‣ Warehouse Management ‣ Incoming Shipments

Warehouse ‣ Warehouse Management ‣ Internal Moves

Warehouse ‣ Warehouse Management ‣ Delivery Orders

When you decide to scrap some products, they are transferred to the Scrap location. To display the content of this Virtual Location, go to :menuselection: Warehouse –> Inventory Control –> Location Structure, then select the virtual locations and display the Scrap location.

If you want to transfer the products to another location, you can create a new one and check the Scrap Location in the additional information.

Identifying Products and Locations with Barcodes and RFID Devices¶

You can the barcode in the product form in the field EAN13.